Dieser Artikel beschreibt die Komponenten für den Antrieb des Big Rob die ich selber gebaut oder gekauft habe. Der Antrieb beschreibt all die Komponenten die benötigt werden die Räder zu befestigen und auch diese anzutreiben. Die Getriebemotoren sind sehr stark und das ist auch der Grund warum der Antrieb selber sehr stabil ausgelegt wurde. Zusätzlich zu dem hohen Drehmoment der Motoren soll auch die Zuladung des Roboters hoch genug sein um noch eine zusätzliche Box auf dem Roboter aufsetzen zu können für weiteres technisches Equipment.

Das folgende Bild zeigt die wichtigsten Komponenten die ich gekauft habe um mit dem Entwurf des Antriebes loslegen zu können.

- Nummer 1: Ist eine 8mm im Durchmesser starke Silber-Stahl Achse. Ich habe eine Achse mit den Maßen 8mm x 500mm gekauft und in vier Teile zerschnitten.

- Nummer 2 & 3: Das sind die Befestigungen für die großen Buggy Räder. Das ist eine typische Befestigung von Reely um Räder auf einer Achse befestigen zu können. Genauer sind es Reely 511492C Aluminium CNC gefräste Sechskant Verschraubungen.

- Nummer 4: Dabei handelt es sich um ein Kugellager. Ich habe diesen Typ von Kugellager verwendet um die Antriebsachse zu lagern.

- Nummer 5: Das ist ein weiteres Kugellager das ich mir gekauft habe um die Achse zusätliche zu unterstützen. Ich habe diese Kugellager aber nicht in meinem Roboter verbaut.

Bei dem Zuschnitt der Antriebsachsen hatte ich Unterstützung von dem Betrieb www.metallbau-kick.de aus Garching der gleich in meiner Nähe seinen Firmensitz hat. Mein Dank geht an dieser Stelle an die netten und Hilfsbereiten Mitarbeiter von Metallbau Kick.

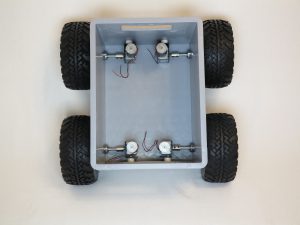

Der erste Entwurf der Antriebseinheit sieht wie im folgenden Bild gezeigt aus. Da die Achse mit 120 mm sehr kurz ist konnte ich nur ein Kugellager in meinem Roboter verbauen. Aber dieses eine Kugellager sollte ausreichen.

[DE_BOOK_DETAIL DE_BOOK_DETAIL=”DE_BOOK_DETAIL”]

Das nächste Bild zeigt die Antriebsachse zusammen mit dem Getriebemotor. Eine zusätzliche Kupplung sorgt für die Verbindung zwischen Motor und Antriebsachse. Diese Kupplung hat ebenfalls eine 8 mm Bohrung.

Als Motoren habe ich günstige 12 V Motoren vom Typ GW31ZY verbaut. Diese Motoren gibt es mit verschiedenen Übersetzungen und Geschwindigkeiten. Ich habe 12 V Motoren mit 35 U/min genommen. Diese haben ein Drehmoment von 15 kg/cm was für den Roboter sehr gut reicht.

Die graue Plastikbox zu bearbeiten ist sehr einfach. Ich habe dazu eine ganz normale Bohrmaschine und Holzbohrer genommen. Ich habe ein paar Minuten investiert die beste Position für die Motoren zu finden und habe anschließend das Loch für die Antriebsachse gebohrt. Damit die Getriebemotoren im Roboter befestigt werden können habe ich L-Profile gekauft die genau zu den Motoren passen. Anschließend habe ich die Motoren zusammen mit der Antriebsachse in den Roboter eingebaut. Anschließend habe ich die Position des Kugellagers pro Antriebsachse markiert und die Löcher für die Befestigung der Kugellager gebohrt.

Das nächste Bild zeigt den Roboter von innen mit den eingebauten Motoren und Antriebsachsen.

Roboter Komponenten Liste

Das ist die Liste der Komponenten die ich verwendet habe um den Antrieb zu bauen. Ich habe die Teile bei Amazon bestellt da es sehr einfach ist und ich mit Amazon immer sehr gute Erfahrungen gemacht habe.

Alle weiteren Komponenten für den Bau des Roboters wie der Raspberry Pi oder der Motortreiber sind in der folgenden Komponentenübersicht aufgeführt.

Roboter Auto – Komponenten Liste

Bei der Wahl des Motortreibers lesen Sie bitte folgenden Artikel: Big Rob – Motortreiber

Das folgende Bild zeigt den Big Rob bei -12 °C wie er im Schnee herum fährt.

Zusammenfassung

Das schwierigste bei diesem Projekt war es alle Komponenten für den Antrieb des Roboters zu finden. Ich habe viele Stunden damit verbracht die Komponenten zu suchen und mir Gedanken über den Aufbau zu machen. Mit der Reely Sechskant Radbefestigung war es dann ganz einfach die großen Buggy Räder auf der 8 mm Achse zu befestigen. Die starken 12 V Getriebemotoren sind perfekt als Antrieb für den Roboter. Aktuell versorge ich den Roboter mit Strom aus zwei 7,2 V Akkus dich ich in Reihe geschalten habe und so 14,4 V erhalte. Mit diesen 14,4 V kann ich die Motoren und restliche Elektronik im Roboter sehr gut mit Strom versorgen.

Artikelübersicht - Big Rob:

RASPBERRY PI ROBOTER – BIG ROB BAUANLEITUNGRASPBERRY PI ROBOTER – PEAK POWER PACK STROMVERSORGUNG

RASPBERRY PI ROBOTER – BIG ROB 4×4 ELEKTROMOTOR ANTRIEB

RASPBERRY PI ROBOTER – BIG ROB MOTORTREIBER BTS7960B UND SOFTWARE

RASPBERRY PI ROBOTER – BIG ROB OUTDOOR-KAMERAGEHÄUSE

RASPBERRY PI ROBOTER – BIG ROB mit differential GPS

RASPBERRY PI ROBOTER – BIG ROB ZÄHNE

RASPBERRY PI ROBOTER – BIG ROB FAHRWERK OPTIMIERUNG

RASPBERRY PI ROBOTER – BIG ROB modularer Aufbau 1-2

RASPBERRY PI ROBOTER – BIG ROB modularer Aufbau 2-2

1A ich werde mir das Buch holen!

Oli